A Little Something That Sparkled My Day, And How It All Began

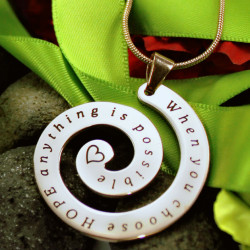

You know, sometimes the simplest of moments can truly set the wheels spinning in this old head of mine. I was sat, not so long ago, watching the morning sun catch the dew on a spider's web in my garden – just a fleeting second, but the way those tiny droplets caught the light, each one a miniature rainbow, perfectly strung along delicate, almost invisible threads, it was absolutely captivating. It sparked a thought, a little whisper about how something so understated could hold such incredible brilliance, and how that brilliance could be arranged in a way that wasn't strictly linear, but rather danced across the eye. That’s the sort of quiet wonder that often inspires me when I'm sketching new pieces, and it was certainly what got me thinking about our beautiful Diagonal Dazzle Ring With 2-3 Gemstones, a truly special creation that just makes your heart sing. We’ve poured so much of ourselves into perfecting every single aspect of these gorgeous pieces, hoping they bring you as much delight as they bring us during their creation. It's about taking those everyday moments of beauty and turning them into something tangible, something you can wear and cherish, something that carries a little bit of that natural, understated magic with it, every single day. We truly believe in creating jewellery that tells a story, a story that begins with a flicker of inspiration and ends with a cherished treasure, and the Handmade Diagonal Dazzle Rings are a perfect example of that journey from concept to reality.

Now, getting something as seemingly straightforward as a glint of light on a web into a piece of jewellery, well, that's where the real alchemy happens, isn’t it? It starts with a vision, a feeling, and then it transforms into intricate designs on paper, and eventually, into precious metal and dazzling gemstones. We wanted a ring that wasn’t just round and traditional, but one that had a bit of a quirky spirit, a gentle twist, something that caught the eye from every angle. The asymmetrical band was born from that desire for a unique flow, a contemporary feel that still felt utterly classic. And the diagonal line of gemstones, those two or three little sparks of pure colour, they represent those scattered moments of brightness in life, perfectly aligned to catch the light, just like those dewdrops. It’s a design that speaks of individual style, of a quiet confidence, and of the stories we carry with us. When you wear one of these rings, you're not just wearing a piece of metal and stone; you're wearing a little piece of that initial inspiration, that gentle morning glow, brought to life by our skilled hands. It’s a testament to the idea that beauty can be found in unexpected places, and that even the smallest details can make the biggest statements, something we keep in mind for every design, whether it's a simple pendant or an elaborate necklace.

The Careful Dance of Our Supply Chain: More Than Just Materials

Right, let’s talk shop, shall we? You might not think much about where the metals and stones for your beloved pieces come from, but for us at AOL Special, it's absolutely fundamental, truly at the heart of everything we do. It’s not just about getting hold of some silver or a few bits of gold; it's about nurturing relationships, ensuring ethical sourcing, and maintaining a steadfast commitment to quality from the very first spark of an idea right through to the finished article. Our supply chain is a carefully orchestrated dance, a network of trusted partners we’ve cultivated over many, many years. For instance, our .925 sterling silver, which is a fantastic foundation for so many of our pieces, including the Diagonal Dazzle Ring, arrives from highly reputable refiners who share our values regarding responsible and sustainable practices. We're talking about folks who adhere to strict international standards for both environmental protection and labour practices, meaning you can wear your ring with a clear conscience, knowing it’s been handled with care every step of the way, right from its origin.

And then there are the precious metals for our white, yellow, and rose gold options – oh, they’re a whole world unto themselves! Each alloy has its own specific recipe, a precise blend of pure gold with other metals like copper, silver, or palladium, all chosen for their ability to bring out that particular hue and ensure the metal is strong enough to last a lifetime. We work closely with our metallurgists, the clever chaps who know everything about these alloys, to guarantee that our gold is not only beautiful but also holds up to the rigours of daily wear. They ensure the perfect balance for casting and setting, making sure the metal flows just right in the mould and can securely hold those precious gemstones. This meticulous attention to the composition of our metals is paramount, whether we’re crafting a delicate Silver Gold Necklace or a robust wedding band, because the integrity of the material is the very backbone of the jewellery.

More Than Just Sparkle: The True Worth of Your AOL Special Piece

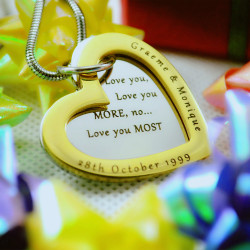

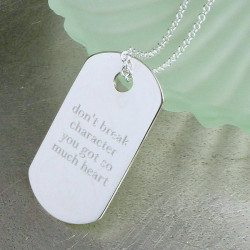

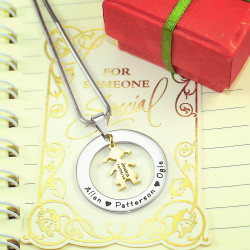

So, you’ve heard a bit about the passion behind the design and the sheer dedication we pour into sourcing our materials. But what does that really mean for you, holding one of our Diagonal Dazzle Rings in your hand? Well, it means a lot, actually. This isn't just a pretty bauble; it’s a story waiting to be told, a symbol of connections and milestones. You choose those two or three 2.5mm round gemstones – perhaps the birthstones of your children, your best mates, or even significant dates in your own life. Imagine having a little flash of emerald for a May birthday and a brilliant sapphire for a September anniversary, all nestled together, sparkling on your finger. And then, there's the engraving! We can meticulously etch names, dates, or a secret message right there on the band, alongside each birthstone, making your ring uniquely, wonderfully yours. It truly transforms a lovely piece of jewellery into something deeply personal, a wearable memory, a tangible hug for your finger, if you will. The whole idea is to create something that resonates with your heart, much like how a carefully crafted Sterling Silver Arabic Necklace can connect someone to their heritage and personal story, becoming more than just an adornment.

Taking care of your new treasure is pretty straightforward, I promise. These rings are designed for life, meant to be worn, loved, and perhaps even passed down through generations. To keep that beautiful diagonal dazzle shining its brightest, a gentle clean with a soft cloth and a little mild soapy water every now and then is usually all it takes. For a deeper clean, especially if you've got some intricate engraving or gemstone settings, a soft brush can help get into those nooks and crannies. We also recommend bringing your ring in for a professional check-up every year or so, just to make sure those settings are still perfectly secure and the metal is looking its best. Think of it like taking your beloved vintage car for a service – a little TLC goes a very long way in ensuring its longevity and continued brilliance. And while we’re talking about rings that last, we also apply the same rigorous standards to pieces like our Rocky Outcrop Ring, ensuring its rugged beauty endures just as powerfully as its distinctive design.

The Magic Unveiled: Inside the AOL Special Workshop

Now, this is where the real fun begins, and where I get to truly indulge in my love for the craft. The manufacturing process of our Diagonal Dazzle Ring is where all those design dreams, ethical materials, and emotional connections really come to life. It’s a painstaking journey, a symphony of precision, patience, and good old-fashioned skill. It all starts with the design, of course. Once my sketches get the nod, they move into the digital realm, becoming a precise 3D CAD model. This isn’t just about looking fancy; it allows us to meticulously plan every curve of that asymmetrical band, the exact angles for the gemstone seats, and the precise width – 4.9mm for the 2-stone, 7.1mm for the 3-stone – ensuring structural integrity and aesthetic perfection. This digital blueprint becomes our guide, guaranteeing that the final piece will be exactly as envisioned, a truly bespoke fit and feel. This initial stage is so vital, setting the tone for every subsequent step, ensuring that when we begin the Hands-on work, every measurement is accounted for.

From the digital model, we create a high-resolution wax prototype, usually through a very clever 3D printing process. This wax model is an exact replica of your ring, ready for its fiery transformation. It's then carefully attached to a 'tree' with other wax models, all ready for investment casting. This is an ancient technique, essentially. The wax tree is encased in a special plaster-like compound, which then hardens. Once solid, this 'investment' is placed in a high-temperature kiln, where the wax melts away completely, leaving a perfect, hollow mould of the ring. This part always feels a bit like magic, watching the form appear from the void, and it’s the foundation for every single piece we create, whether it's a subtle pendant or a chunky Mens silver oxidized band ring.

Next up, the metal, the very heart of the ring. Whether it's the crisp sheen of .925 sterling silver or the warm glow of yellow, white, or rose gold, the molten metal is poured or injected into that perfectly formed mould. We use centrifugal casting for a lot of our rings, where the mould spins at high speed, forcing the liquid metal into every tiny detail and crevice, ensuring a dense, bubble-free casting. Once cooled, the investment material is broken away, revealing the raw metal ring, still attached to its sprue (the channel the metal flowed through). It’s a bit rough around the edges at this stage, certainly not the polished beauty you’ll eventually wear, but you can already see the promise, the delicate lines of the asymmetrical band beginning to take shape. It’s a fascinating moment, a moment of birth for your future heirloom.

The journey from a rough casting to a gleaming piece of jewellery is where the artisan truly shines, and it's certainly where my team and I spend the bulk of our time and passion. The sprue is carefully cut away, and then the real clean-up begins. Each ring is meticulously filed and shaped by hand, removing any casting imperfections and refining the contours of the band. We're talking about millimetre precision here; the band width of 3.4mm for a 2-stone ring and 6mm for a 3-stone ring must be absolutely spot on, ensuring comfort and aesthetic balance. This stage is all about bringing the ring's design to life, smoothing out any edges, and preparing the surface for what’s to come. It's a dance between various grades of files and increasingly fine abrasives, slowly but surely coaxing the raw metal into its intended form. It requires a steady hand and a keen eye, the kind of detailed work that makes our Custom hand-painted monogram bangles truly distinctive.

With the band perfectly formed, it's time for the pre-polishing stage. This involves a series of progressively finer abrasive compounds, applied with various spinning buffs, slowly but surely removing all those tiny scratches and marks left from the filing and shaping. It's a gradual process, revealing the metal's natural lustre step by painstaking step. Each ring is then carefully prepared for stone setting. For our Diagonal Dazzle Ring, with its two or three 2.5mm round stones, precise holes are drilled along that diagonal line. These holes aren't just empty spaces; they're meticulously cut 'seats' that will cradle each gemstone securely. The exact angle and depth are critical here, ensuring that when the stones are set, they sit perfectly flush, catching the light beautifully and appearing as a seamless part of the design. We prepare the metal around these seats to be easily worked for the final setting, a delicate balance of strength and pliability. This meticulous preparation is what ensures the security and brilliance of every single gem, whether it’s in this ring or a Handmade Gold Monogram Initial Bracelet.

Now for the pièce de résistance: stone setting. This is a moment of intense focus and a real test of skill. Each 2.5mm round gemstone, whether it’s a vibrant sapphire, a deep garnet, or a sparkling diamond, is individually placed into its prepared seat. Using specialised tools, the surrounding metal is then carefully pushed over the stone, forming tiny, secure beads or bezels that hold the gem firmly in place. It's an intricate dance of force and finesse, ensuring the stone is secure without putting any undue pressure on it, allowing it to truly dazzle. We check each stone from multiple angles, ensuring perfect alignment along that diagonal line, and that every single facet is ready to catch and reflect light. It’s amazing to watch the ring truly come alive as each gem is set, adding that vibrant splash of colour and sparkle. And then, for that extra personal touch, the engraving! Using a fine burr or a laser engraver, the names of loved ones or special dates are meticulously etched onto the band, right next to their corresponding birthstones. This step requires an incredibly steady hand and an artist's precision, transforming the metal into a canvas for cherished memories. It’s a truly moving part of the process, making each ring deeply unique, much like how every character on a Harrington Name Necklace is carefully crafted to perfection.

Once the stones are set and any engraving is complete, the ring undergoes its final polish. This is where it truly transforms from a carefully crafted piece of metal and stone into a breathtaking work of art, ready to adorn your finger. We use a series of ultra-fine polishing compounds and soft buffing wheels, each one designed to bring out the maximum lustre and shine from the metal. Every surface, every curve, every tiny nook and cranny of that asymmetrical band is polished to perfection, ensuring a smooth, luxurious feel against your skin. The goal is a mirror-like finish, where the metal reflects light beautifully and those gemstones truly pop. It's a labour of love, a testament to our unwavering commitment to quality, because we know that the final presentation is just as important as the initial design. This meticulous finishing touch is applied to all our pieces, from a delicate band to a bold Men's Dome Brushed Baguette Ring, ensuring everything that leaves our workshop is nothing short of perfection.

And finally, before any Diagonal Dazzle Ring leaves our workshop, it goes through my personal inspection – and believe me, I'm a stickler for details! I check everything: the security of each gemstone, the smoothness of the metal, the clarity of the engraving, and the overall finish. I run my fingers over every curve, inspect the settings under magnification, and ensure it meets the incredibly high standards we've set for ourselves here at AOL Special. It's not just about passing a quality check; it's about ensuring that each ring embodies the passion, the care, and the craftsmanship that has gone into its creation, from the moment of inspiration to the final polish. We want you to feel that connection when you wear it, that sense of a truly bespoke piece, lovingly made just for you. Every single Sterling Silver Ring we craft undergoes this rigorous final review, guaranteeing that what you receive is nothing less than impeccable. So, when your beautiful Diagonal Dazzle Ring arrives, know that it's been on quite a journey, nurtured by skilled hands and a whole lot of love, all the way to your door.