A Whisper of Silver and a Glimmer of Grit: Our Hammered Bangle's Story

Hello, lovely people! It’s your resident chief jewellery aficionado, chief artisan, and general busy bee here at AOL Special, ready to pull back the curtain on something truly special. There is something utterly captivating about a piece of jewellery that, despite its simplicity, holds a world of stories, a tactile connection to the artisan's touch, and the very essence of enduring style. I was just yesterday admiring how a Tiny Silver Raindrop Necklace catches the light, each facet reflecting a miniature world, and it struck me, once again, how sometimes the simplest forms, born from nature's subtle cues, hold the most profound beauty. It's that same quiet elegance, that understated charm, that we infuse into every piece we create, especially when working with metal and hammer, where the raw material is transformed by intention and skill.

It often crosses my mind how much human endeavour goes into creating something that looks effortlessly graceful on your wrist or around your neck. The journey from a block of metal to a wearable work of art is a marathon, not a sprint, a testament to dedication and precision, qualities we hold very dear. One can consider the resilience and strength needed, much like the qualities embodied in a Trail Men's Tungsten Ring, which is forged to withstand the rigours of everyday life and adventurous spirits. This understanding of materials, their inherent properties, and how they respond to our touch, forms the bedrock of our craft here at AOL Special; it is a respect that we extend to every material, be it silver, gold, or the hardiest of metals. We recognise that each material has its own personality, its own way of shining, and we aim to bring that out.

The Unseen Threads: Weaving Our Supply Chain Magic

Now, let's talk shop, shall we? You might not think much about where the silver in your beloved bangle comes from, but for us, it is a saga in itself, a tale of meticulous selection and unwavering standards. We are not simply picking up any old bit of metal from the corner shop; absolutely not. Our sterling silver, the beautiful 925 variety that forms the backbone of our Silver Hammered Bangle, begins its journey far earlier than it ever graces our workshop. We establish very close relationships with our suppliers, individuals and companies who share our very strict ethical standards and commitment to quality, ensuring that the silver we work with is not only of the purest composition but also sourced responsibly. Even for something as dainty and intricate as a Unique personalized handmade butterfly charm, the provenance of the metal is paramount, as the entire piece is only as good as its starting components.

The journey of our 2.4mm square sterling silver wire, specifically, is something that truly warms my artisan's heart. It starts as raw silver, extracted from the earth, then refined to an astonishing purity of 99.9% fine silver. This fine silver then makes its way to specialist alloyers who, with scientific precision, combine it with just the right proportion of copper – 7.5% to be exact – to create sterling silver. This specific alloy, by the way, is what gives our jewellery its strength, its beautiful lustre, and its ability to be worked by hand, transforming from a simple wire into something truly extraordinary. It is a carefully managed process, right from the initial smelting through to the drawing of the wire to our precise specifications, something that allows us to craft even the delicate components for a Handmade Carrie name bracelet anklet with full confidence in the material's integrity.

Our supply chain management, believe me, is not a dry, dusty affair; it is a living, breathing network of trust and shared values. We are in constant communication with our suppliers, checking on the latest certifications, discussing the environmental footprints of their operations, and ensuring that every single strand of wire, every sheet of metal, meets our incredibly high benchmarks. This also means we keep a watchful eye on market fluctuations for precious metals, ensuring we secure the best possible quality without compromising our ethos or fair pricing for our customers. The global landscape of precious metals is, as you might gather, quite a complex beast, but we navigate it with a steady hand, always prioritising the long-term well-being of both our craft and the wider world. It is a commitment that shines through every piece, whether it is a weighty bangle or a delicate Gold monogram bracelet.

The Bangle's Heart: Value, Versatility, and a Lifetime of Lustre

So, you are holding one of our Silver Hammered Bangles, perhaps feeling its reassuring weight, running your finger over the beautifully textured surface. What exactly is it that makes this piece, forged from a simple length of 2.4mm square wire, so incredibly special? Well, for a start, sterling silver itself possesses an enduring appeal; it's a metal with a rich history, known for its cool lustre, its versatility, and its remarkable ability to complement almost any outfit, any skin tone, any occasion. It is not something that screams for attention, but rather, it quietly commands it, a statement of understated elegance that speaks volumes about the wearer's discernment. This piece, you see, is not just a circle of metal; it is a circular narrative, a continuous loop of craftsmanship and personal expression. We are very proud of the fact that we do not just sell jewellery; we create cherished possessions, pieces that are bought to be worn, loved, and eventually passed on, much like the timeless appeal that makes someone choose to Buy tiny silver star necklace.

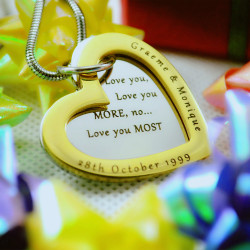

The beauty of our bangles lies in their ability to be incredibly personal, despite not being explicitly engraved. Each Silver Hammered Bangle tells a unique story through its texture, no two hammered finishes are ever exactly alike, even from the same artisan's hand. This makes each bangle a truly unique expression of the craft. Wear it on its own, a solitary gleam on your wrist, letting its subtle texture catch the light and draw admiring glances. Or, and this is where the real fun begins, stack it! Mix and match with other bangles, perhaps a highly polished one, or one with a different texture; the possibilities are endless. This layering creates a dynamic, individual look that evolves with your mood and style, a testament to the versatility we build into our designs. We often chat with customers about how their choice of jewellery, whether it is a delicate chain or a bold statement piece, is a deeply personal declaration, much like deciding to Personalize Your Cross Name Necklace, making it uniquely yours and reflective of your journey.

Taking care of your sterling silver bangle is also quite straightforward, something we believe is important for any cherished item. Silver does like a bit of attention now and then, a gentle polish to keep it gleaming. The natural oils from your skin generally help to prevent tarnishing with regular wear, but if it does start to look a little dull, a quick rub with a special silver polishing cloth will bring back its original sparkle. It is a little ritual, a moment of connection with your piece, an acknowledgement of its place in your life. We package every item, including this bangle, in a beautiful gift box, ready to be opened and loved straight away, or to be presented as a thoughtful present to someone special. We always want that initial experience to be truly lovely, a little moment of anticipation and delight, much like the anticipation someone feels when receiving a Personalized Footprint Necklace, knowing it carries a unique and sentimental value.

The Artisan's Dance: From Wire to Wearable Art

Right then, let's get down to the nitty-gritty, the heart and soul of what we do here: the making. This is where the magic truly happens, where raw material, skilled hands, and a bit of pure passion come together to create something beautiful. It starts, as I mentioned, with our lovely 2.4mm square sterling silver wire. This wire arrives in coils, usually around a metre or so long, carefully protected and gleaming. The first thing we do, even before a single cut is made, involves a thorough visual inspection. We are checking for any imperfections, any tiny scratches, or discolourations that might have occurred during transit or production. This initial quality check is absolutely vital; a pristine starting material makes for a pristine finished piece, something that sets our standard for everything from a delicate WV State Necklace to the most robust of our rings.

Once we have given the wire our seal of approval, it is time for the workbench. My workbench, I should tell you, is a universe of tools: hammers of every size and shape, mandrels, files, pliers, torches, and polishing motors – each one a trusted friend, an extension of my hand and intention. The air in the workshop often carries the faint, comforting scent of polishing compound, metal, and sometimes, if I am being honest, a bit of strong coffee. For a Silver Hammered Bangle, the first step after selection involves precise measurement. Our bangle sizes, from small at 19cm up to extra-large at 22cm circumference, require exact calculations to determine the length of wire needed. We account for the thickness of the wire itself and the slight material loss during forming and soldering, a tiny fraction, but something that makes all the difference in achieving the perfect fit.

Now, silver wire, straight off the reel, can be a bit stiff and stubborn. So, our next step, before we even dream of shaping it, involves annealing. This is where the magic of fire comes into play. We carefully heat the silver wire with a jeweller's torch, watching as it glows a soft cherry red in the dimly lit corner of the workshop. This process softens the metal, making it pliable and much easier to work with, rather like kneading dough until it is ready to be shaped. Without annealing, the silver would simply crack and resist our efforts, making it impossible to form into a smooth, even circle or oval. It is a beautiful dance between flame and metal, a controlled transformation that prepares the silver for its true purpose, releasing any internal stresses built up during the wire-drawing process.

With the wire now soft and compliant, the shaping begins. For the circular bangles, we use a steel mandrel, a perfectly round, tapered metal rod. We carefully wrap the annealed wire around the mandrel, coaxing it into a beautiful, flowing circle. For the oval shapes, we employ a slightly different technique, often combining specific shaping pliers with a custom-made oval mandrel. This part of the process requires a very steady hand and a gentle, consistent pressure to ensure the resulting shape is as perfectly symmetrical as humanly possible. We are not rushing this stage, you see; every curve, every bend is a deliberate act, contributing to the overall integrity and comfort of the finished bangle. It is akin to sculpting in miniature, where every fractional adjustment matters immensely for the final aesthetic.

Once we have a near-perfect circle or oval, the two ends of the wire need to meet and become one. This is the soldering stage, a point where precision and patience are absolutely paramount. The ends are carefully filed perfectly flat and flush against each other, creating a gapless join. A tiny sliver of silver solder, an alloy with a lower melting point than the bangle wire itself, is then placed precisely over this join. With the torch, we apply heat very carefully, drawing the solder into the joint by capillary action. You have to watch it like a hawk; too much heat, and you melt the entire piece; too little, and the solder will not flow properly, leaving a weak joint. When done right, the solder literally disappears into the silver, becoming an invisible bond, a testament to the seamless artistry we strive for.

After soldering, the bangle often has a rather dull, sometimes discoloured appearance due to the heat. This is where our 'pickle' bath comes in. It is a gentle, acidic solution that removes any fire scale or flux residue, leaving the silver clean and bright again. We then rinse the bangle thoroughly in clean water to neutralise any remaining pickling solution. Now, the bangle is officially a continuous circle, but it is still quite soft from the annealing and soldering process. It needs some work-hardening to make it durable for daily wear, and this is where the eponymous hammering comes in, an almost rhythmic choreography of tool and metal, where the silver sings under the hammer's embrace.

Ah, the hammering! This is arguably the most character-defining stage for our Silver Hammered Bangle. I select a hammer, usually one with a slightly domed or rounded face, to impart that beautiful, organic texture. We do not just bash away indiscriminately, no, no, no! Each strike is deliberate, each tap is aimed to create a specific, light-catching facet. We place the bangle on a highly polished steel anvil, or sometimes a specialised forming stake, and then, with a steady hand and a controlled rhythm, the hammering begins. The blows are not overly heavy; they are spaced evenly, creating a fascinating landscape of tiny indentations and raised surfaces across the entire circumference. This hammering process not only imparts that unique, beautiful texture but also, rather cleverly, hardens the silver, making the bangle much stronger and more resistant to bending or deforming with everyday knocks and bumps. It is a truly satisfying part of the process, hearing the gentle ping of metal against metal, knowing that with each strike, a piece of unique character is being forged into the silver.

Once the hammering is complete, we move onto the refinement of the shape. Even with the utmost care, hammering can sometimes slightly distort the perfect circle or oval. So, back to the mandrel it goes! We gently re-shape the bangle, using a rawhide mallet to tap it carefully, coaxing it back into its intended form without damaging the newly created texture. This is a very delicate operation; we are correcting the geometry while preserving the artistry of the hammered surface. We check it from every angle, spinning it on the mandrel, ensuring that it sits beautifully and evenly. It is a continuous dialogue between the material and the artisan, a dance of adjustment and perfection, making sure that every piece, whether it is a weighty bracelet or a delicate pendant, maintains its true form. You might have seen some of the meticulous measurements we take when designing, for example, a Tiny Silver Raindrop Necklace; the same precision applies here, even for what seems like a simple form.

Next up, it is time for the clean-up and pre-polishing. The hammering can sometimes leave tiny, sharp edges or burrs, which we carefully remove with very fine files and emery paper. We start with coarser grades to smooth out any larger imperfections, then gradually move to finer and finer grades, essentially erasing the traces of the tools and preparing the surface for its ultimate finish. This is a messy stage, with silver dust flying, but it is absolutely essential for creating that smooth, luxurious feel against the skin. We then take the bangle to the polishing motor, where we use various buffing wheels and polishing compounds. For a high-shine finish, we meticulously work through several stages of compounds, starting with a coarser one to remove any remaining scratches, and finishing with an ultra-fine compound that brings out a mirror-like lustre. For a soft satin finish, we employ a specialised brushing technique using a satin-finishing wheel, which creates a beautifully diffused, almost pearlescent glow, rather than a direct reflection. Each finish is chosen to complement the individual piece and the wearer's personal style, ensuring it feels just right. This level of detail in finishing, you might recognise, is exactly what goes into creating a beautiful, smooth surface for a Gold monogram bracelet.

Now, a truly essential part of our process, and something that speaks volumes about our commitment to quality and authenticity, is hallmarking. Once the bangle has been shaped, hammered, and primarily polished (but before its final mirror shine or satin brush), it makes a very important journey to the London Assay Office. This ancient institution, with its centuries of history, is where the silver is independently tested for its purity. Our sponsor's mark, the standard mark (the lion passant for sterling silver), the fineness mark (925), the Assay Office mark (the leopard's head for London), and the date letter are all struck into the bangle. This is not just a legal requirement; it is a badge of honour, a guarantee of genuine quality and ethical practice, a hallmark of our integrity. It is a fantastic reassurance for anyone considering a new piece, offering confidence in its authenticity, much like the trust we build when you choose to buy a Tiny Silver Star Necklace, knowing it is genuine sterling silver and crafted with care.

Once our bangle returns from the London Assay Office, proudly bearing its marks of authenticity, it undergoes its final polish and clean. For the high-shine pieces, this means a last, loving buffing to ensure every surface gleams perfectly. For the satin-finished bangles, it is a final, careful brushing to achieve that perfect, soft glow. Both then go into an ultrasonic cleaner, where high-frequency sound waves gently remove any lingering polishing compounds from the crevices of the hammered texture, followed by a steam clean for an immaculate finish. Then comes the final, very critical quality check. I personally inspect every single Silver Hammered Bangle under magnification, checking the soldering joint, the evenness of the hammering, the perfection of the polish, and the clarity of the hallmarks. If it meets my incredibly high standards – and believe me, they are high – only then does it get packaged, nestled safely and beautifully in one of our signature gift boxes, ready to begin its new life with you, a tangible piece of our passion, skill, and British craftsmanship, ready to adorn your wrist and become a part of your own unique story. This entire meticulous process, from selecting the finest wire to the final quality assurance and packaging, embodies our commitment to creating jewellery that is not merely an accessory but a cherished heirloom, a piece that carries history, craftsmanship, and a touch of something truly special, something handcrafted with heart and soul for you to cherish.