A Little Chat About Life's Tiny Treasures and Big Meanings

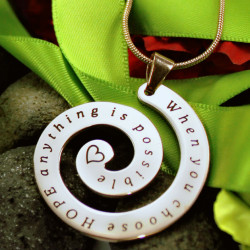

You know, it's funny how a little glint of something can spark a whole world of memories. I was just pottering about the other day, helping my niece pick out a locket for her mum's birthday, and she pointed to a picture of her grandad. He’d given her nan a rather special piece years ago, a delicate thing, full of love and a bit of sparkle, much like our lovely Personalized Angels Rose Gold Necklace. It got me thinking about how these bits and bobs aren't just metal and stone; they're tiny vessels for our biggest feelings, aren't they?

It’s that feeling, that warmth, that sense of holding onto something truly special, that often sets off a little lightbulb in my head. A moment, a story, a connection – these are the real gold, I reckon. Just the other week, a young couple came in, absolutely beaming, wanting something truly unique to celebrate their newest arrival. There was such a quiet joy about them, a hopefulness that just bubbled over, and it got me thinking about how we encapsulate those first precious moments, perhaps with something as tender and meaningful as a Personalized Baby Necklace, marking that tiny, perfect start to a brand-new chapter.

Every single day, we're surrounded by these stories, and each one adds a layer to the pieces we lovingly make. We're not just crafting rings or necklaces; we’re trying to catch a little bit of that human magic, that unique story, and hold it in a tangible form. It's a proper privilege, really, getting to be a tiny part of someone's grand adventure, helping them find that perfect little something that speaks volumes without a single uttered word. That's the real heart of it all, that connection, that personal touch that makes a piece genuinely theirs, and ours.

The Sterling Story: Where Our Silver Gets Its Shine

Right, let’s get down to the nitty-gritty, shall we? You might wonder where all this gorgeous silver comes from and why it matters so much. We don't just wave a magic wand, you know! It's a whole dance, a proper careful ballet, making sure we get the very best for our creations. Our sterling silver, the stuff we use for those delightful bands measuring a precise 2.5mm in width and 1.2mm in thickness, comes from sources we trust, places that share our commitment to doing things properly, ethically, and with a bit of heart. It’s not just about getting metal; it’s about getting the *right* metal, with a clear conscience attached to every gleaming ingot.

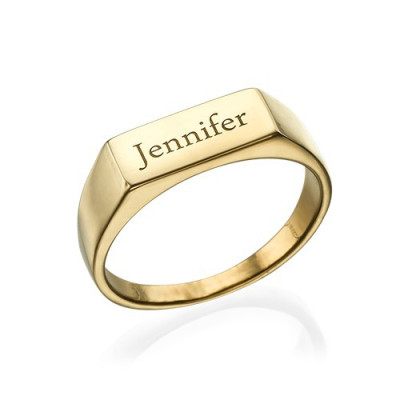

We’ve cultivated relationships with our suppliers over years, building up a rapport, ensuring that every batch of silver is top-notch, with that 92.5% purity mark that makes it 'sterling'. It’s a bit like choosing the best flour for a prize-winning cake, honestly; you wouldn’t skimp, would you? And just as we're meticulous about our silver, we extend that same care across the board. When we’re considering pieces that call for a touch of gold, perhaps for a rather grand Engraved gold signet, we apply the very same rigorous standards, ensuring the metal's provenance and quality are absolutely beyond reproach. It's about consistency, about knowing exactly what goes into every single piece we make, from start to finish.

There are always challenges, mind you. Ensuring that steady stream of high-quality metal, navigating the global market’s little quirks, and making sure our partners adhere to the stringent standards we expect – it's all part of the daily jigsaw puzzle. But it's a puzzle we genuinely enjoy solving, because it means that every raw material that makes its way to our workshops is worthy of becoming something truly cherished. It’s a deep respect for the material itself, knowing the journey it’s taken from the earth to our hands. This respect translates into the very fabric of pieces like our Artisan Love Ring, where the integrity of the material is as crucial as the craft that brings it to life.

That Special Something: Getting Up Close with the Stacking Rings

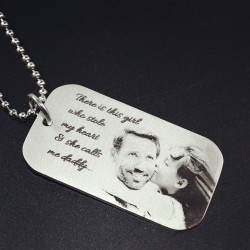

Now, let's have a proper chinwag about our star of the show today: the Personalised Sterling Silver Stacking Ring. Oh, these beauties! They’re just so versatile, aren’t they? Each band is a perfect little sliver of sterling silver, exactly 2.5mm wide and 1.2mm thick. That particular dimension isn’t by accident, you know. It's carefully considered to offer enough presence on your finger, a lovely tactile weight, while still being slender enough to stack comfortably, allowing for that wonderfully unique layered look. And the best bit? We can engrave both sides! A name, a date, a secret message – whatever your heart desires, we can etch it there, turning a lovely ring into a whisper just for you, or for someone special.

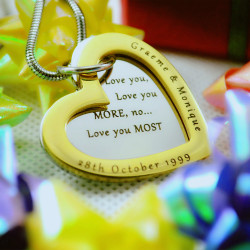

The beauty of personalisation, whether it's on a ring or a delightful little trinket, is just unparalleled. It takes a piece from being 'a nice ring' to 'my ring', imbued with meaning only you (or the lucky recipient) truly understand. Thinking about those special moments, say, a milestone birthday or an anniversary, a thoughtful Personalized heart bracelet gift can carry that sentiment so perfectly. It’s about creating a little slice of permanence, a tangible reminder of a moment, a person, a feeling that means the world. And caring for these pieces? It’s wonderfully straightforward, which is always a bonus.

To keep these treasures looking their absolute best, a little TLC goes a long way. If you notice any tiny bits of dust or general everyday grime clinging on, a quick scrub with a soft toothbrush can work wonders, getting into all those nooks and crannies. Think of it like giving it a gentle little spa treatment! Regular cleaning keeps the lustre alive, ensuring your pieces stay looking as new and bright as the day they first arrived. And when it comes to finding your perfect fit for any of our rings, we've got you sorted with our handy Sizing Tool – a super helpful PDF you can print off. You can pop an existing ring onto the circles to find your size, or snip out the measuring bar and wrap it around your finger. We always suggest trying both methods, just to be absolutely sure you’ve got it spot on. It’s worth the extra minute, truly, for that perfect fit, because a well-fitting ring is a happy ring!

The Hands-On Magic: Crafting Perfection, Bit by Bit

From Raw Form to Radiant Ring: The Alchemy of Our Workshop

Alright, grab a cuppa, and let’s spill the beans on how we actually make these little wonders. It’s not just a case of picking up a lump of silver and giving it a stern look, you know. There’s a whole lot of thought, care, and a rather considerable amount of elbow grease that goes into every single one. Our workshop is a buzzing hive of activity, a place where metal transforms, where ideas take physical form, and where a bit of soul gets poured into every piece. It all starts with those carefully sourced sterling silver ingots, gleaming blocks of potential just waiting to become something extraordinary. We’re talking about a process that’s as old as time, yet continually refined with modern precision and a healthy dose of experience.

The first step, once our silver arrives and passes its own meticulous internal checks, is melting. Oh, the heat! It’s quite a sight, watching that solid metal yield to the intense warmth, turning into a shimmering, molten pool. From there, it's carefully poured into moulds, creating long, even rods. This is where precision really starts to matter. Any inconsistencies now will show up later, so we’re utterly focused, ensuring a smooth, flawless pour. We cool these rods slowly, making sure the metal's molecular structure is as robust as can be, preparing it for the rigours to come. It’s a fundamental stage, setting the tone for the entire journey, whether it’s for a simple band or something more intricate, perhaps even for a Personalized Eiffel Charm, where every angle and curve relies on a perfectly prepared metal base.

Once we have our cooled silver rods, the real shaping begins. This involves drawing the silver through a series of ever-smaller dies. Imagine spaghetti being squeezed through a press, but with metal! It's a gradual process, thinning the rod down bit by bit until we achieve exactly the right thickness for our stacking rings – that 1.2mm we talked about. This drawing process also work-hardens the silver, making it stronger and more durable. But too much hardening, and it becomes brittle, so we regularly anneal it – gently heating it to soften it up again before continuing the drawing. It’s a delicate balance, this dance between strength and malleability, a constant dialogue with the material itself, coaxing it into its desired form.

After we’ve got our perfect length of silver wire, the next step is to create the ring’s basic shape. Each length is meticulously cut, then carefully bent and formed into a circle. This isn’t a quick job, you see. We use a mandril, which is a cone-shaped tool, and a rawhide hammer, gently tapping and shaping until the ends meet perfectly. Any gaps here would mean a weak joint, and we're not about that life! For something like a Handmade geometric square ring, this shaping process becomes even more of an art form, demanding absolute precision in every corner and angle to maintain its crisp, architectural lines. It's all about attention to detail, making sure the very foundation of the ring is faultless.

Then comes the soldering. This is where those perfectly aligned ends are joined, using a tiny piece of silver solder and a focused flame. It’s a blink-and-you’ll-miss-it moment, a flash of heat, and then, a seamless join. You want that solder joint to be practically invisible, melting smoothly into the surrounding silver, becoming one with the band. Once cooled, we quench the ring, then pickle it in a mild acid solution to remove any fire scale – that slightly tarnished layer that forms during heating. This reveals the bright, clean sterling silver underneath, ready for the next stage of its transformation. It's a satisfying part of the process, seeing that dullness disappear and the true metal shine through.

Now, onto the smoothing and refining! Once the ring is shaped and soldered, it's still a bit rough around the edges, literally. We use a variety of files and emery papers, starting coarse and gradually moving to finer grits. This removes any tiny imperfections, tool marks, or excess solder, making the surface beautifully smooth. It’s all done by hand, mind you. There’s no rushing this; it’s a meditative process of gentle abrasion, ensuring every millimetre of the ring's surface is absolutely flawless to the touch. It's this painstaking care that gives our pieces that wonderful, buttery feel against the skin. We wouldn’t want any snagging, would we?

After the filing and sanding, it's time for the polishing. This is where the magic really happens, where the silver truly comes to life, achieving that characteristic gleam. We use various polishing compounds and different buffs on our polishing motor, moving from coarser compounds to ultra-fine rouges. It’s a multi-stage process, each stage adding a layer of lustre, coaxing out the metal's inherent shine. The room gets filled with a soft hum and a bit of dust, but the results are always worth it. The final polish leaves the ring with a mirror-like finish, reflecting the light beautifully, just ready to catch someone’s eye. It truly is a sight to behold when a piece goes from a dull matte to a dazzling shine.

The Personal Touch: Engraving and Final Checks

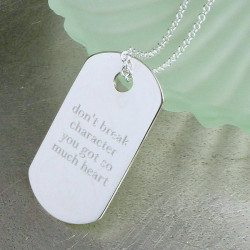

This is where your story truly begins to embed itself in the metal. For our Personalised Sterling Silver Stacking Rings, both sides can be engraved, which is pretty neat, isn't it? Whether it's a date, initials, a meaningful word, or a secret message, our engraving experts meticulously etch your chosen words onto the band. We use a combination of traditional hand-engraving techniques for that authentic, deep cut, and modern laser engraving for incredible precision and consistency. It’s a delicate job, making sure every letter is crisp, perfectly spaced, and beautifully aligned. Each stroke is purposeful, transforming a piece of jewellery into a profound statement, a whisper made permanent. This careful process is also what goes into creating a bespoke item like a Handmade Personalized Opposites Attract Bracelet, ensuring every individual element, every carefully considered detail, comes together harmoniously.

After the engraving, each ring goes through a rigorous quality control check. This isn’t just a quick glance, oh no. We scrutinise every single aspect: the smoothness of the band, the integrity of the solder joint, the perfection of the polish, and, of course, the clarity and accuracy of the engraving. We’re looking for anything, even the tiniest imperfection, that doesn’t meet our exacting standards. If something isn't absolutely spot on, it goes back for refinement. Only when we’re completely satisfied, when the ring feels right in the hand, looks impeccable to the eye, and passes every test, does it move on to its next stage. It’s a commitment to excellence, right down to the last molecule, because we know you’re trusting us with something special. We would apply this same stringent approach if you were to Shop two stone rings, ensuring the setting and security of each gem is absolutely perfect. Every piece, regardless of its specific design, receives the same level of care and attention before it leaves our doors.

And there you have it, a little glimpse behind the curtain, into the heart of how these gorgeous rings come to life. From that initial spark of an idea, through the careful sourcing of our sterling silver, to the intricate dance of crafting, polishing, and finally, personalising, it’s a journey filled with passion and precision. Every single step, every meticulous detail, is handled with the utmost care, because we understand that what we create isn't just an object; it’s a memory, a sentiment, a piece of your story. It’s a wonderful thing, really, getting to make these little bits of wearable art, knowing they’ll be cherished for years and years to come.